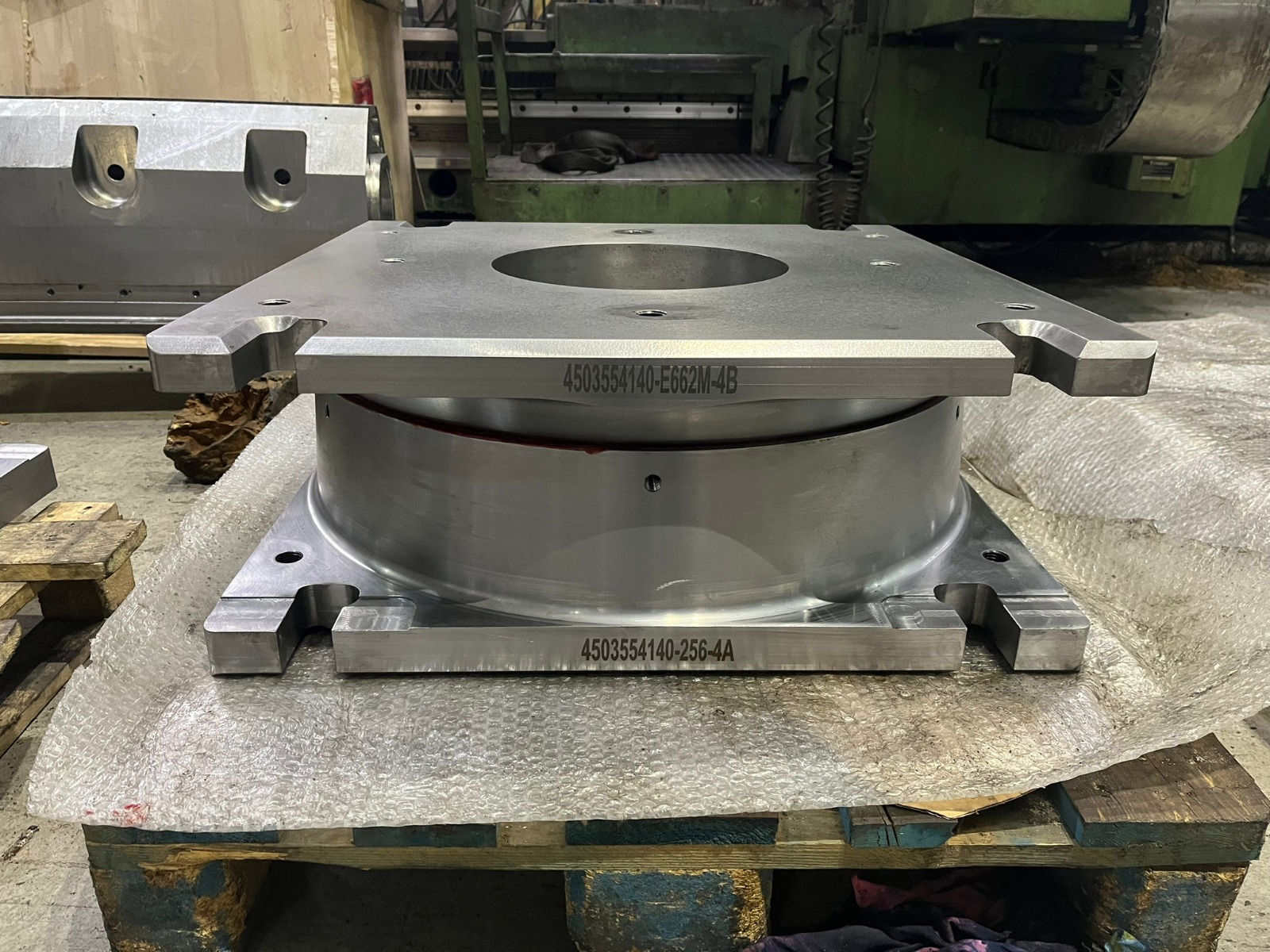

TURNING BOWLS (Draaikom)

SKU: UNI-DRAA

At UNIMA, we manufacture large-scale turning bowl (Draaikom) components used in heavy-duty rotating assemblies, strictly based on customer-provided technical drawings.

These parts are critical load-bearing structures in rotary systems and must meet strict mechanical and dimensional requirements.

🔧 Key Features

- Material & Heat Treatment

Manufactured from cast, forged, or structural steel. Stress relief or normalizing can be applied if required. - CNC Machining

High-precision turning and milling in line with customer tolerances.

Conical/cylindrical machining

Bolt hole patterns, centering details

Surface tolerance: up to ±0.01 mm - Bronze Weld Overlay

For high-friction surfaces, a bronze overlay can be applied to internal faces. This enhances wear resistance and extends service life. - Lubrication Channels

Custom lubrication grooves (spiral, linear, circular) can be machined on bronze surfaces as specified. - Quality Control

3D dimensional reports

Weld and surface inspections

Material certificates and optional NDT reports

PRODUCT INFO

It can delivered after NDT controls after production.

It can be produced with alternative material qualities.

SHIPMENT INFO

Production times vary depending on the order quantity and current stock status. Approximate production time is 30 pieces / day and shipment time varies between 15-45 working days depending on the location. When you request an offer for the product quantity you want to order, the delivery date will be specified.